Step-By-Step Process for Metal Castings

Stainless Steel Investment Castings by Lost Wax Process in Steel alloys, Bronzes & Aluminium alloys.

Investment Castings today is a highly specialized method of producing near net shape. Advantages are smooth and pleasing finish, reduced machining allowances, close tolerances, fexibility of alloy selection etc.Castings can be made with undercuts, through or blind holes and tapers. We produce castings in the weight range from a few grammes to about 15 Kgs single piece. The method of production at Trident Steels is given below in detail.

Kindly contact us for more details or for best prices.Trident Steels, today, offers Investment castings at very competetive prices.

Trident Steels also manufactures Stainless Steel castings of pipe fittings in S.S304 and S.S316 grades. These are machined on CNC machines.

|

|

|

|

|

|

|

|

|

|

|

|

|

Trident Steels solicits work from inland as well as foreign buyers to meet its spare capacity. We are currently supplying to various industries like valves, pumps, textile, sewing machines, automobile, electrical / electronics and general engineering industries. Kindly send us your drawings for a immediate response as well as for a very competetive price for Investment castings.

Bronze investment casting, copper investment casting

Investment casting, generally utilized for the development process of complex-shaped components or parts that need tighter, tolerances, thinner walls and better surface finish in comparison to other process obtained with sand casting, is the most crucial process to make mould in convenient way. Investment casting is required frequently by the aerospace, medical fields, and military. Now, it is used in varied other industries for diverse types of metals. You can get bronze investment casting and for other types of metals too like copper investment casting. Investment casting is used to create parts with superior dimensional accuracy, where finished forms are often produced without secondary machining. There is a lot more associated with the investment casting process.

We at Trident Investment Castings are well-aware of the increasing importance of bronze investment casting and copper investment casting. We follow a world-class process of international standards to ensure you will be getting the best use of every piece of metal. There is a lot more associated with the advanced process. Trident Investment Castings has a team of dedicated professionals easing entire process and providing you with complete peace of mind.

Copper Alloy or Bronze Investment Casting

Bronze Investment Castings are extensively used in Pump and Valve manufacturing industries. They are also used in Earth moving machinery.

We, at Trident Steels, manufacture investment castings in Bronze grades such as Gun Metal 85/5/5/5, Aluminium Bronze AB1 and AB2, PCuSn7, 88/10/2, PB1, PB2, Nickel Silver grade C97600 etc.

Our Bronze investment castings are characterized by beautiful finish and aesthetic looks.

Before starting working on the process, we listen to you carefully and provide you with the right solutions. Our main motive is to provide you with the best casting processes. Check all details, know about the metal types, and leave rest of the work on experts working with us.

Feel free to contact us as per your requirement for hassle-free and successful process of copper investment casting and bronze investment castings.

Investment Casting Process – Step-by-Step

Investment casting process needs more attention and proper care. For your convenience and to help you in getting the right solutions, we have come up with the points to understand the entire process successfully.

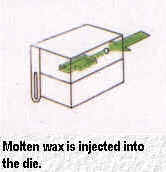

- The investment casting process starts with the wax pattern that is removed from the die

- In the further processing, the patterns are assembled in a cluster or tree, where the branches are in-gates.

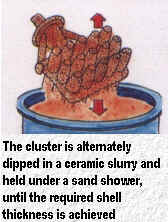

- The process continues with the wax cluster that is dipped in ceramic slurry

- It held under falling ceramic powder

- The cluster is alternately dipped in a ceramic slurry and held under a sand shower until it required shell thickness achieved

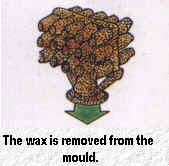

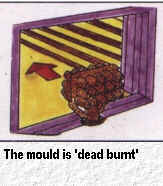

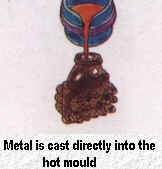

- The wax is removed from the mould and the mould is dead burnt to cast the metal directly into the hot mould.

- As soon as the mould is knocked out, the pieces are removed from the runners and sprues and the ingate is ground off.

- The final process starts with dispatching as a die is made to inject wax patterns; while the molten wax is injected into the die.

Each and every step is done in a planned way and step by step. From experienced engineers, you will get the right solutions and complete peace of mind. You need to not worry about anything related to investment casting. There is no need to get your own setup developed as the experts are here to solve your queries at Trident Investment Casting. We guide you and ensure you will get the right solutions. There is a lot more associated with the entire process. Our engineers will clear your doubts and provide you with the right solutions.

Kindly contact us for more details or for best prices. Trident Steels, today, offers Investment castings at very competitive prices.

Trident Steels also manufactures Stainless Steel castings of pipe fittings in S.S304 and S.S316 grades. These are machined on CNC machines.

Trident Steels solicits work from inland as well as foreign buyers to meet its spare capacity. We are currently supplying to various industries like valves, pumps, textile, sewing machines, automobile, electrical / electronics and general engineering industries. Kindly send us your drawings for a immediate response as well as for a very competitive price for Investment castings.

Leave us a message